Ilkeston Town Walk - Stage 09 - Cluny Lace Co Ltd

w/e 04 May 2003

The answer to the poser in Stage 08 of the Town Walk

is of course "LACE" and the factory on Belper Street

is owned and managed by the eighth and ninth generations of the

Mason family. It goes by the name of Cluny Lace and the company

has been the proud manufacturers of the finest Leavers lace since

1845.

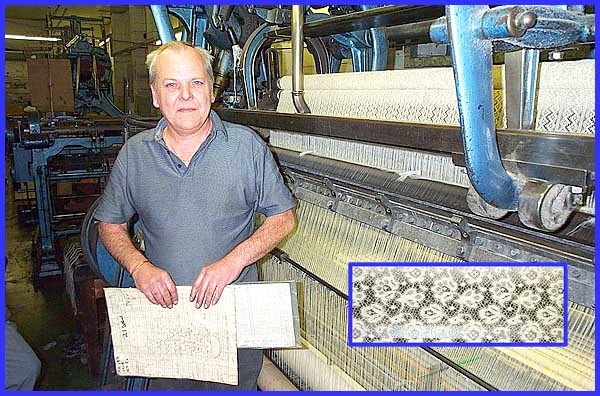

Our guide, John, took time off from his normal duties to show

my wife Sandra and myself, around one of the workshops on the

ground floor. John is seen here clutching one of the intricate

patterns that he uses to set up the machines, the inset shows

the result of his labours as it appears on the machines.

|

|

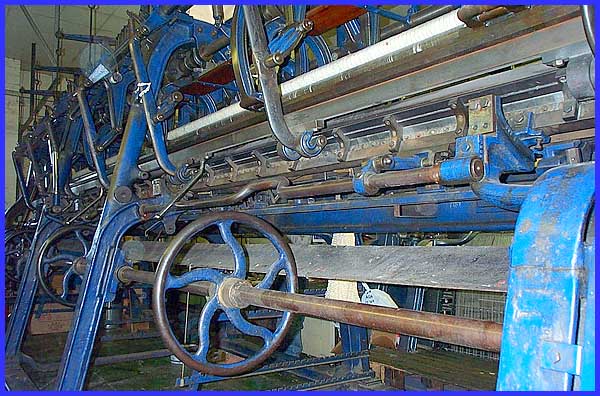

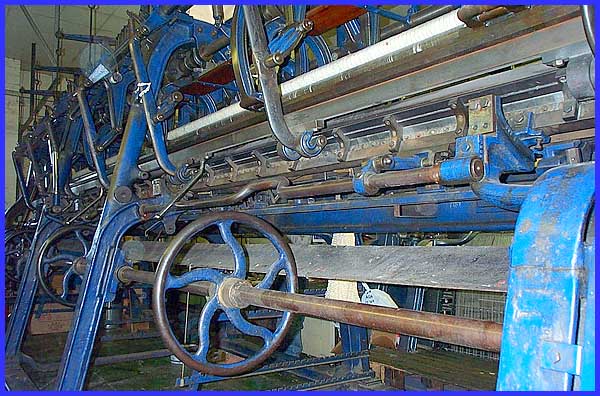

I provided three clues in Stage 08, the first

being an Egyptian import. That was the fine cotton thread that

is used in the manufacture and the view above is from the rear

of one of the machines. Cotton accounts for over 95% of the material

used in most of the laces produced in the factory. Small amounts

of polyester and nylon are used in some of the products.

|

|

|

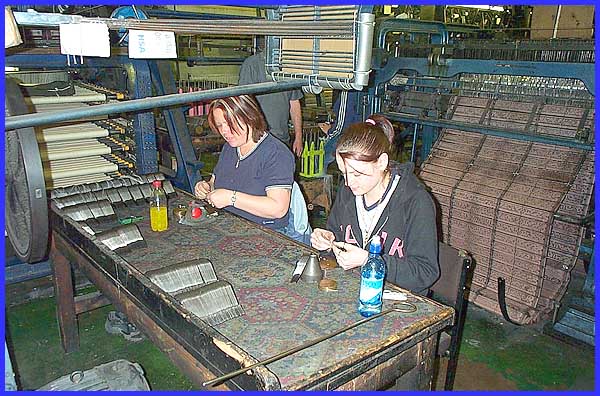

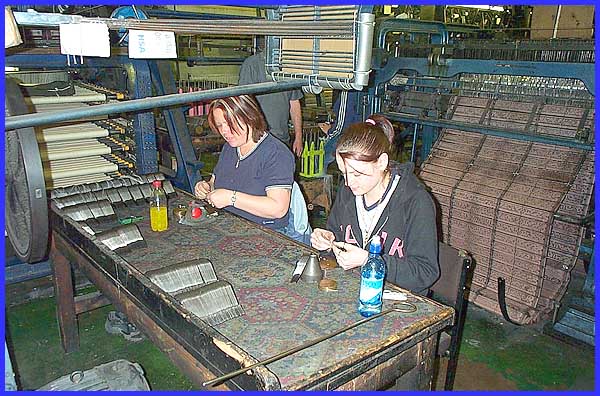

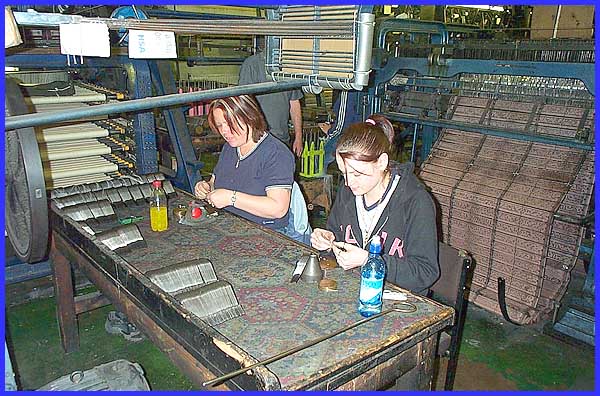

Hundreds of the "metal objects", the second

clue, are used on the machines after being fitted with discs

holding the thread to become the bobbins. You can see them stacked

up on the table in the photo as they are prepared for the machines.

With the bottles of orange and water on the table, it looks like

thirsty work!

|

|

|

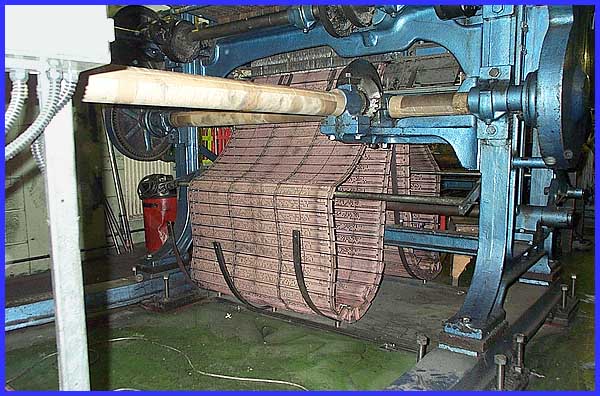

The third clue was the name of John Jardine on one

of the machines. All six of the machines in this workshop were

manufactured for export by John Jardine of Nottingham which is

less than ten miles away. Cluny Lace have rescued, re-imported,

renovated and refurbished them for use in this factory in Ilkeston.

The one above is still in need of some work but will soon be

in production too.

|

|

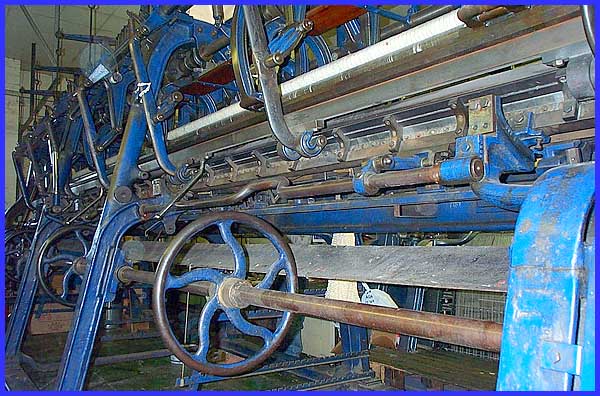

To produce the intricate patterns on the lace the bobbins are

jiggled back and forth by means of thin metal rods or plates

that run along the length of the machine. They are programmed

to move by a punched card system similar to those that are often

seen on old fairground organs.

|

Of the six machines in the workshop, one came from France, one

from the USA, two from Austria and two, including the biggest

ever made, from Canada. When fully laden each machine weighs

about 20 tons. It is easy to understand why they are on the ground

floor. The next floor up has medium sized machines and there

are small machines on the third storey. I marvelled at the ingenuity

of the designers of these machines for although the two largest

were built in 1960 and 1962, the original design dates back to

the early nineteenth century. They started out as steam powered

machines, then generators were used before their progression

to computer controlled electrically. Just moving with the times.

As a bonus to this Stage of the Town Walk, you can click on the

image below to see a panoramic view of the whole workshop. All

that remains is to extend our thanks once again to the company

for giving us the opportunity to see lace making at close quarters

and to John for showing us around. If you would like to know

more about the history of the Cluny Lace Co Ltd, please click on the name

to visit their web site.

|